Innovations in Green Roofing and Integrity Testing

Advertisement

Adhering to the ASTM Standards is Critical for Effective Quality Assurance

We are all in an amazing business. Working together, we deliver wonderful outdoor living areas that provide incredible benefits to our customers. They are not only very special amenities - beautiful and delightful recreational spaces to satisfy the soul - but they also have numerous hugely practical benefits such as energy cost reduction, improved air quality, biodiversity, moderation of the heat island effect, storm water control and much more.

Our green roofs have extraordinarily high rates of customer satisfaction … unless (and I hate to even say this) … the roof leaks. While all roofs need to perform well, the bar is particularly high for vegetative roofing, since it can be costly to fix a leak after a green roof is implemented. How can we use integrity testing innovations to ensure that our new membranes are breach free and watertight?

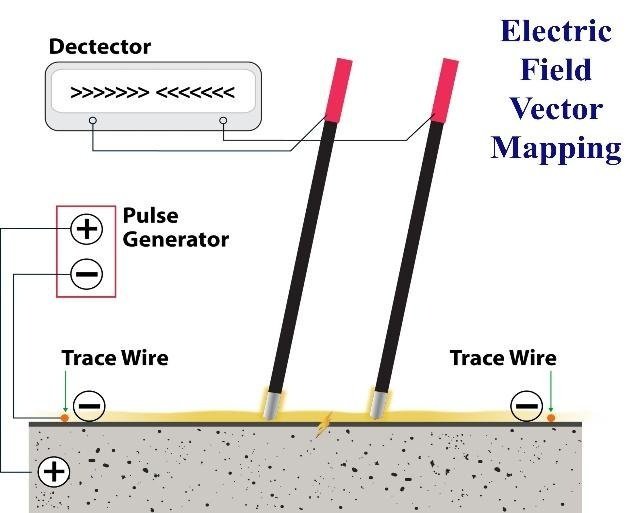

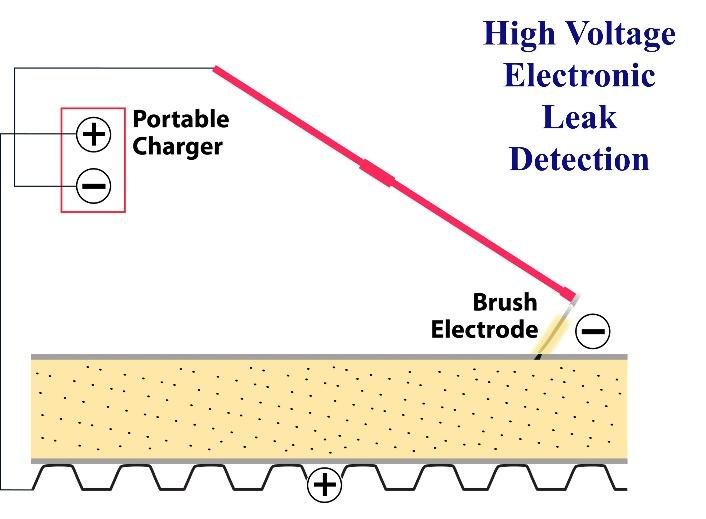

Electronic Leak Detection: While hit or miss flood testing had been used for many years for Quality Assurance (QA) the innovation of Electronic Leak Detection (ELD) in the 1990’s was a huge leap forward in integrity testing. It gave us the ability to confidently deliver 100% leak free vegetative roofing assemblies. While each Electronic Leak Detection procedure has advantages and disadvantages in specific situations, all can provide highly accurate Quality Assurance results … when the necessary conditions are present. Low Voltage Electric Field Vector Mapping, High Voltage ELD, the Low Voltage Scanning Platform and the Low Voltage Vertical Roller can all ensure that we are delivering watertight assemblies. However, it is critical to understand that the test procedures require a high-quality electrical ground immediately available under the membrane if thorough and accurate testing is to be provided.

Immediately Accessible Grounds are Paramount: The ELD test procedure can only work when an electrically conductive ground is available to accept the test currents. Structurally reinforced concrete decks are excellent grounds. Thorough and accurate leak detection can be conducted when Inverted Roof Membrane Assemblies (IRMA) roofs are installed directly on these substrates. However, a new challenge emerged when the test techniques were applied to conventional insulated roofing systems. It quickly became clear that inaccurate testing would occur when there were materials like insulation and cover boards between the membrane and the conductive deck. These materials were both thermally insulating and electrically insulating and thus prevented the test currents from reaching the ground and completing the circuit required to locate any breaches.

Image 1: Inverted Roof Membrane Assemblies can be tested with 100% accuracy when the membrane is applied directly on a highly conductive ground like structurally reinforced concrete. Note electrical connection is made through the breach. Photo: IR Analyzers

Image 2: Testing conventional insulated roofing systems can result in false negatives (failure to identify breaches) when electrically insulating materials like cover boards and insulation are present between the membrane and the conductive deck or grounding medium. Note no connection is made as the ground is not available

Advertisement

American Society for Testing and Materials: ASTM has responded to this challenge by issuing two Electronic Leak Detection (ELD) standards that directly address the question of alternative grounds and proper ground positioning to ensure 100% accurate ELD. Both D7877 and D8231 require “placing a conductive material directly under the membrane” when the electrical path to the conductive deck is interrupted. [emphasis added]

Alternative Ground Innovations: In order to install insulated assemblies that are ELD ready, the roofing industry typically provides two options to serve as alternative grounds for accurate testing. Conventional assemblies now receive either a stainless-steel wire mesh, or an electrically conductive primer as an alternative ground. Stainless steel mesh is an excellent conductor of electricity. However, most manufacturers will not approve their membranes being installed directly over a wire mesh. This has often led to the installation of the wire mesh under the cover board. Unfortunately, gypsum, cementitious, and high density isocyanurate cover boards are electrically insulating and prevent the passage of current to the wire mesh. This scenario does not meet the applicable ASTM standards and can create false negative integrity test results; the conditions you are testing for (breaches) are present, but the test incorrectly reports that there are none. An exception can sometimes be made for conventional systems with substantial service life. They can often be candidates for forensic (leak) testing when there is sufficient water saturation in the assembly to conduct the current to ground.

Another industry innovation is an electrically conductive primer (TruGround® Conductive Primer) that can be applied to the top of the cover board or insulation. This has been a significant breakthrough in green roofing Quality Assurance because conventional insulated systems can now be tested with the same accuracy as IRMA systems. Most manufacturers have now completed laboratory testing on the primer and approved this product for use with their membranes. Some have even received (or are applying for) Factory Mutual (FM) approval. Use of the primer allows for membranes to be applied directly on the alternative ground and meet both ASTM Standards. This allows ELD service providers to operate with 100% confidence that the test procedures will not be subject to the false negative results inherent in testing when the ground is not directly available to receive the test currents.

Most manufacturers have approved TrueGround Conductive Primer as an alternative grounding medium that can be applied directly under the membrane, satisfying the ASTM Standards and proving 100% accurate testing. Photo: Detec Systems

Leak Detection Through Green Roofing: Another cautionary tale involves the ability of ELD to pinpoint leaks in assemblies with the overburden already in place. Much has been made of the ability of Electric Field Vector Mapping to not only be applied to exposed membranes, but even through overburden like green roofing, pavers, ballast, etc. However, as a practical matter, there are numerous challenges involved when attempting to locate leaks through the overburden and in many instances results from the field have been inconclusive. The procedure requires interpretation of electrical patterns on the surface of the membrane buried under the overburden materials. These low voltage, low amperage electrical patterns are quite subtle and become weakened, unreliable, or even disappear as the overburden gets thicker. In addition, there can be a variety of metal objects in the overburden that can act as grounds for the test currents and create false positive results by appearing to be leaks. While Electric Field Vector Mapping does have some potential to locate leaks under these conditions, as a practical matter many of these tests have not performed satisfactorily and building owners have been disappointed when it was not possible to locate their leaks under these conditions. It's important for all stakeholders to understand that there is no guarantee that accurate testing can be conducted with the green roof overburden in place even though the conductive wires are present on the membrane surface.

Advertisement

TruGround is a water-based, quick drying, highly conductive alternative ground. It is easily applied to the top surface of the insulation or cover board to comply with the applicable ASTM Standards, and provide 100% accurate ELD testing.

Specifications: The presence of wood or other non-conductive decks, insulation and cover boards, vapor retarders, etc. in the assembly will require specifying an alternative ground that is not only sufficiently conductive but also adheres to the ASTM Standards with placement directly under the membrane.

Bottom Line: There is no substitute for a top quality ELD Quality Assurance survey on the exposed membrane before any overburden is installed. The testing must be conducted with a high-quality ground available directly under the membrane for 100% accurate results. It is also critical that an independent and experienced third-party test provider conduct the ELD test procedure on the exposed membrane surface before the installation of any overburden to ensure delivery of a breach free watertight assembly.

Advertisement

Peter Brooks has over 40 years’ experience in nondestructive testing of roofing and waterproofing assemblies. He is President and CEO of IR Analyzers.

TruGround® Primer is manufactured by Detec Systems, Ferndale, WA and IR Analyzers distributes TruGround Conductive Primer in the Northeastern U.S.