Understanding the Behaviour of Fire and Green Roofs

Advertisement

A lot has been said and written about green roofs and fire safety which is inaccurate. Regulations and norms can vary from country to country, even sometimes from one city to another. Furthermore, the gap in the scientific research on fire and green roofs means we are left to draw conclusions from private research or extrapolations from research conducted on standard roofing systems.

The fire safety of green roofs had not been assessed scientifically until a doctoral candidate at Laval University in Québec City chose to devote her research to this matter. Nataliia Gerzhova spent 3.5 years conducting various tests and numeric modelling and has published three peer reviewed articles about her research. Her results will be discussed here and should help to shed some light on exactly how a green roof can impact a fire risk to a structure and how different elements in green roof perform under extreme temperatures - alone and compared to standard roofing systems.

The Mountain Equipment Co-op green roof in Downtown Toronto was not serviced for many years, but vegetation was still healthy in 2019. Photo Courtesy Roxanne Miller.

In an attempt to design safe green roofs, a significant experimental research was conducted in Germany in the 1980s. Based on the results, the first fire protection measures were developed and made part of the German green roof design Guideline FLL (1). There is an opinion that green roofs can reduce the spread of fire, and it was mentioned that in the past some green roofs were installed for this purpose. This belief is due to the fact that plants are about 95 per cent water. But what happens when the vegetation dries up? Poorly maintained green roofs with overgrown vegetation could ignite and spread fire.

In the private sector, various testing has been done and documented. For example, we have seen green roofs and waterproofing layers intentionally exposed to a roofer’s torch. However conclusive those testing results might have been, they can hardly be used to issue regulation.A more standardized, monitored, and reproducible methodology for testing was needed to scientifically prove what we observe on the roof.

To conform to building regulations, roof coverings are evaluated with standard ASTM E108 - Standard Test Methods for Fire Tests of Roof Coverings. Photo courtesy Island Style Roof.

To conform to building regulations, roof coverings are evaluated according to test standards CAN/ULC-S107 in Canada, or ASTM E108 in the United States. The samples are tested for their ability to resist the spread of flame and downward flame propagation through the deck. Even though green roof manufacturers successfully tested their assemblies following these standards, the test method was designed for roofing systems, not a consistent depth of low organic content growing media and green roof specific components. Due to the great variety of plants found on green roofs, their complex configuration and properties that change with time, it is difficult to say whether these testing methods can correctly classify green roofs. This raises the question of whether the existing testing methods are suitable not considering the fire risks of the green roof itself. This might be why what we can see in written regulation is so diverse and concerns all aspects of the green roofs (vegetation-free zones, parapet heights, type of vegetation, type of roof decks, organic content of green roof media, etc.). This lack of scientific studies also brings a lot of confusion when it comes to issuing regulations that concern the roofing system, the building type as well as the roof deck type. For example, some municipalities and organizations will not accept green roof on combustible or wooden frame buildings, like the RBQ (The Régie du bâtiment du Québec - a major quality control organization for the construction industry in Québec). The Toronto Green Roof By-law however, indicates that it is permitted to install vegetated roofs on both combustible and incombustible buildings. The norm ANSI/SPRI VF-1 is a design standard for minimizing fire risk on green roofs and it is used by other municipalities in Canada to allow green roofs on all types of roof decks (metal, concrete or wood).

Advertisement

To tackle this lack of scientific knowledge on green roofs and fire risk, Ms. Gerzhova conducted three separate and detailed studies to assess the fire risks of green roofs. The first concerned thermal conductivity of a dry green roof substrate and its dependency on temperature. The results of this study were then used in the second part of the project, which assessed the potential fire hazard to roof decking. Its main objective was to determine under what conditions the roof deck can be damaged by elevated temperatures. Finally, the third concerned the flammability characteristics of green roofs to assess their fire performance and to compare the results to a standard roofing system. We will review these three studies separately in this article to be able to formulate recommendations for regulations.

Part 1 – A conceptual Framework for Modelling the Thermal conductivity of Dry Green Roof Substrates (2019)

Visible aggregates in green roof substrate have complex thermal conductivity.

This study characterized the thermal conductivity of a dry green roof media and its prediction as a function of temperature. The obtained effective thermal conductivity was subsequently used in the second study in order to conduct numerical simulations of heat transfer process across green roof assemblies.

Validation test equipment for thermal conductivity of growing medium. Photo courtesy Nataliia Gerzhova

Thermal conductivity of soil can be measured directly. However, laboratory equipment does not allow to perform measurements at elevated temperatures. Thus, for this study thermal conductivity of the substrate was obtained using a prediction model of from Côté and Konrad (2009) that allowed to calculate it for a range of temperatures.

Thermal conductivity in soil is a complex process that occurs through solids, fluid phase and through contacts between solid particles. Prediction of this physical property requires taking into consideration several factors, including properties of solids, porosity, and shape of particles, which can greatly affect the thermal conductivity. Moreover, extreme temperatures in fire can induce changes in both organic and inorganic parts of the substrate. For most of the minerals and rocks thermal conductivity changes inversely with temperature. Organic matter undergoes thermal decomposition, that leads to change of proportions in a substrate blend. Finally, an interparticle radiation can occur at extreme temperatures, that greatly increases thermal conductivity.

Figure 1. Effective thermal conductivity of green roof growing medium.

A series of experiments was carried out to collect data to account for all the factors that affect thermal conductivity. First, substrate solids’ parameters, such as density and thermal conductivity were performed. Next, thermogravimetric analysis (TGA) showed stages of the degradation of the organic component, specifically, the greatest mass loss occurred between 250 and 440 °C. Also, the thermal conductivity of the whole growing medium blend at different porosities was measured at normal temperature.

Using data obtained the thermal conductivity at different temperatures was calculated. The resulting predicted effective thermal conductivity shows a great increase with temperature (Figure 1). Its validation with numerical simulation and heat transfer test confirmed the suitability for numerical solutions.

Part 2- Heat Transfer Behaviour of Green Roof Systems under Fire Condition: A Numerical Study (2019)

The potential fire hazard to roof decks covered with vegetation has not yet been fully explored. This part of the study analyzed the performance of green roofs in extreme heat conditions by numerical modelling of heat transfer through the assembly, when the roof is exposed to elevated temperatures from the exterior. The main objective was to determine conditions and time required for the roof deck to reach critical temperature (time to failure). Effects of the heating load applied, substrate layer thickness, porosity of the substrate, the presence of gypsum board over the deck were also examined. It was assumed that no moisture was present in the assembly in order to model the most severe situation.

Advertisement

Cone Calorimeter testing measures the fire reaction. Photo courtesy Nataliia Gerzhova

In this study heating loads between 50 and 200 kW/m² were used, which can be associated with small-scale fires and forest fires, and temperatures equivalent to 623 °C and 1110 °C respectively. Growing media layer thicknesses varied between 3 and 10 cm. Substrate’s porosity between 0.5 and 0.7 represented a more and less compacted state. Two different types of roof decks were chosen: a wooden deck made of plywood 19 mm and a steel deck. Critical temperatures for these materials were set to 300 °C and 538 °C respectively according to EN1995-1-2 (2003) for wood and ASTM E119 (2012) for steel.

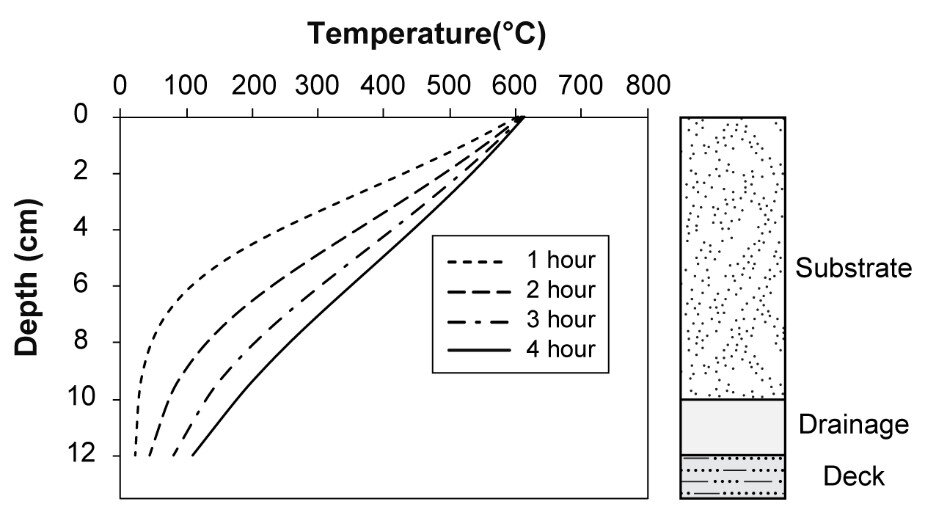

Figure 2. Temperature profiles in the assembly. This graph shows that the substrate protects the underlying deck from fire damage.

Temperature profiles shown in Figure 2 present the result of a heat transfer simulation through a green roof assembly with a 10 cm layer of substrate and a porosity of 0.6 installed over a wood deck not protected by gypsum board during exposure to 50 kW/m² for four hours. The results show that at the deck level no temperature increase was observed after the first hour. In the end of the 4-hour heating period the deck temperature reached 110 °C only, which is well below the critical value, the point at which the deck would have caught fire.

Figure 3. Temperature evolution at the deck level when a green roof is exposed to four different heating loads.

The assembly of the same configuration was then exposed to higher heating loads. Figure 3 presents the temperatures of the deck obtained from numerical model applying heating loads of different intensities: 50, 100, 150 and 200 kW/m². It shows that a deck failure can occur when applying heating load greater than 150 kW/m² and during a period of more than 3 hours. This analysis suggests that a 10 cm layer of growing media insulates well the roof by retarding the propagation of heat for at least three hours when exposed to severe heat load. The German guideline FLL contains a description of a green roof that is considered resistant to radiant heat when substrate layer thickness is at least 3 cm. In Canada and United Stated most green roofs have a minimum of 10 cm, thus making it sufficient to resist the downward propagation of heat to the roof deck.

Figure 4. Time to failure dependency of substrate layer thickness when applying heating loads of 50 and 200 kW/m² in assemblies on the wooden deck with or without protection by gypsum board.

Smaller thicknesses of a substrate layer, however, may not provide such protection. Figure 4 presents how time to failure changes with different thicknesses of substrate. Red curves show the results for the assembly with no gypsum over the wood deck when applying heating loads of 50 and 200 kW/m² for comparison. In both cases time to failure decreases greatly.

From the graph it is clear that using a gypsum board over the roof deck can effectively reduce the fire risk by increasing the time to failure of the structure. Blue curve shows that a delay of at least 30 minutes can be provided for failure time in extreme heat conditions for substrate thicknesses between 3 and 10 cm.

From the analysis of the effect of the substrate’s porosity on fire risks for a roof deck, it was concluded that a better compacted growing media retards better the heat propagation. However, this effect was visible only for high heating loads.

Finally, green roofs installed over steel deck showed better performance in fire, since the structure never reached its critical temperature even in extreme heat conditions and with the growing medium of 3 cm only.

Part 3- Flammability Characteristics of Green Roofs (2020)

The primary concern about green roof and fire risks is the combustibility of green roof components, such as plants and soil organic matter. They are claimed to present an additional fuel load that can contribute to fire. The possibility of such fuel to be ignited and to develop a fire was confirmed by small green roofs fires that happened in Portland (OR), London (UK) and Montreal (Canada) in 2018. From the available information and reports on those cases, sparks ignited dried overgrown grasses. In the Montreal fire, a cigarette butt in a planter was the source of ignition, and fire spread over the roof deck and nearby wall. In all cases the fires were extinguished by firefighters and caused no great damage.

Green roof fire in London UK, 2018. The fire spread to a nearby green wall but did not affect the roof deck.

As studies on flammability of green roof materials are difficult to find, it became clear that this should be the third instalment of Ms. Gerzhova’s doctoral research. Some data on green roof substrate properties can be found in the British report (2013). Soil blend in completely dry condition was tested in order to assess the worst case scenario. Comparison with a substrate containing some amount of moisture, as in real condition, can provide a better idea of the fire hazard of this component, which was explored in this research. Another contributor to fire is vegetation, specifically grass, leaves, small branches and dead plant material. These particles can easily catch fire, especially grasses, having high surface-area-to-volume ratio. The amount of fuel load they present, however, may not be sufficient enough to develop and support large fires. Also, moisture contained in these particles reduces the availability of fuel, meaning that they can act as a heat sink, rather than a source of fuel.

The objective of this study was to determine the potential amount of fuel that a green roof presents, and to examine the Heat Release Rate (HRR, rate at which energy is generated during a combustion of material) produced by substrate and vegetation in comparison with a typical bitumen roof covering.

Figure 5. Comparison of HRRs of vegetation and typical roof coverings: (a) dead parts (Madrigal et al. (2012)); (b) green leaves (Madrigal et al. (2012)); (c) PMB membrane with fire retardants (Bourbigot et al. (2013)); (d) PMB membrane without fire retardants (Thureson and Nilsson (1994)).

Figure 5 shows a comparison of existing data on HRR of vegetation and bitumen roof membranes. It is seen that HRR of plant material, both live and dead, increases rapidly in the first minute reaching high values. In the second minute, however, it rapidly decreases to about 30 kW/m², which is much lower than for the membranes. Whereas HRRs of the membranes remain high for a longer period.

Figure 6. Comparison of heat release rate (HRR) of green roof substrates at dry and moist conditions with bitumen membrane: (a) Substrate 1 (dry); (b) Substrate 2 (dry); (c) Substrate 1 (30% of moisture content); (d) Substrate 2 (30% of moisture content); (e) polymer-modified bitumen (PMB) membrane with fire retardants (Bourbigot et al. (2013)).

The HRR of the substrate was measured using cone calorimeter in dry and moist conditions (30% of moisture content). Two commercial growing media available in Québec containing up to 15% of organic matter were taken for the experiment. The results were compared to existing data on a standard SBS roof membrane with fire retardants tested using the same method (research by Bourbigot et al. (2013).

When comparing the results (Figure 6), it can be seen that the membrane releases heat at a much higher rate and for a much longer period, suggesting a greater potential contribution to the severity of a fire. HRR of dry substrates reach high values but only for the first minute. Substrates containing moisture can be considered as not posing a fire risk.

Conclusion

As a result of this research, we now have a greater understanding of how such varied opinions of green roof fire hazards have sprouted. The 3 parts of the study described here gave us a clear idea of how safe a well designed, installed and maintained green roof can be, when it comes to fire hazards.

It was shown that even though it is difficult to match the vegetation components of green roofs against regular roofing, they still allow us to partially understand the fire hazard that such roofs present on the building in case of fire. From the testing and numerical modelling presented in this article, we can accurately state that the thickness and density of the growing media directly impacts the time to failure of a roof deck caused by elevated temperature. Thicker and denser growing media is better. Even more so, a dry green roof growing media of 10 cm thickness retards efficiently downward heat propagation even when exposed to severe heating loads. A thickness of as little as 3 cm of substrate still has a positive and direct impact by reducing the time to failure of a roof deck.

It was also established that protecting a wooden roof deck by a gypsum board is an effective method of reducing fire risks. When it comes to vegetation, maintenance is the key to minimize fire risks, since a well-maintained green roof does not present a substantial amount of additional fuel load. Finally, and most surprisingly maybe, it was established that green roofs can have a better performance in fire than conventional roof coverings, such as modified bitumen membrane. This was shown by lower values of HRR of the growing medium in dry and moist conditions. This suggest that it is time to revisit regulations that are based on inaccurate fire risk assessments of green roofs, and to switch to a fact based regulation that is representative of the actual fire risk a green roof can have.

Roxanne Miller is a Landscape Architect and green roof specialist with Soprema Canada.

Nataliia Gerzhova is a PhD Candidate at Laval University.

See References Below

References

ASTM International. Standard Test Methods for Fire Tests of Building Construction and Materials; ASTM E119-12-a; ASTM International: West Conshohocken, PA, USA, 2012.

Bourbigot, S.; Cerin, O.; Duquesne, S.; Clavel, N. Flame retardancy of bitumen: A calorimetry study. J. Fire Sci. 2012, 31, 112–130.

Côté, J., and Konrad, J-M. (2009). “Assessment of structure effects on the thermal conductivity of two-phase porous geomaterials,” International Journal of Heat and Mass Transfer, 52(3-4), 796-804. DOI: 10.1016/j.ijheatmasstransfer.2008.07.037

European Committee for Standardization. Eurocode 5: Design of Timber Structures-Part 1-2: General-Structural Fire Design; EN 1995-1-2; European Committee for Standardization: Brussels, Belgium, 2003.

Madrigal, J.; Marino, E.; Guijarro, M.; Hernando, C.; Diez, C. Evaluation of the flammability of gorse (Ulex europaeus L.) managed by prescribed burning. Ann. For. Sci. 2011, 69, 387–397.

Ministry of Housing, Communities & Local Government. Fire Performance of Green Roofs and Walls; Department for Communities and Local Government: London, UK, 2013.

Thureson, P.; Nilsson, M. Degradation of Fire Properties of Approved Products as a Result of Ageing, SP Repot 1994:61; Swedish National Testing and Research Institute: Borås, Sweden, 1994; p. 44